Software and Calibration

Digital blueprints of your i/o solutions

Cri/oSuiteTM – electrical & thermal analysis

Mechanical design

Another important part of the design flow is the mechanical aspects of this system. We can provide a full 3D visualization of the system. All thermal clamps, brackets, and mounting components will be designed to achieve the best available thermalization for your application.

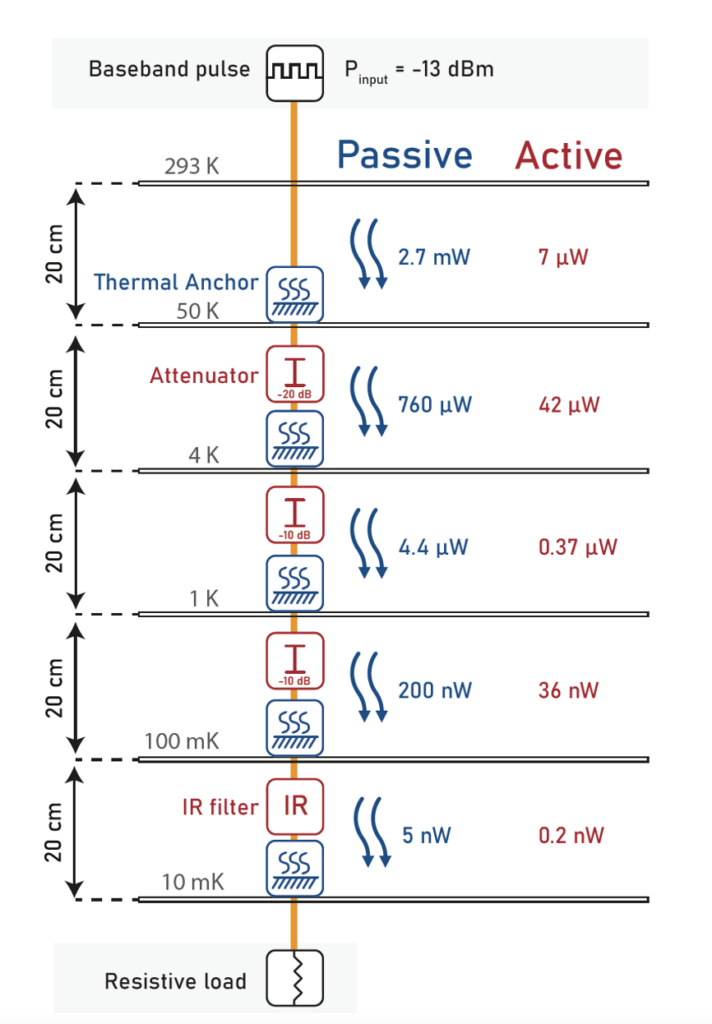

Cri/oSuiteTM example - Power dissipation

To account for the thermal properties of your cryogenic i/o, we have included thermal conduction models, as well as local heating models due to power dissipation. Given a specific temperature profile in a cryostat, we can model the expected temperatures of the Cri/oFlex®, and other components, as well as the expected heat load at each stage. In the example Cri/oFlex® configuration (fig. below), we show the simulated expected dissipative heat load for each segment between cryostat stages. The power dissipation from the baseband pulse generated by room-temperature electronics depends heavily on the components and the signal power. In this example, the attenuator dissipates by far the most power, and should therefore be positioned at a location where the cryostat has sufficient cooling power. Performing these simulations allows our engineers to optimize a desired i/o chain to the customer’s needs.