Connectors

High performance connections with minimal footprints

The i/o chain features three points of interfacing:

- Outside the fridge (between room temperature electronics / cables and Cri/oFlex®), for which multichannel coaxial SMA- and SMP blocks are available;

- Inside the fridge between two flexes (e.g. to go from the Ag- to the NbTi platform), for which our high density Tabbi/TM connectors are developed

- Between the flex and the quantum device, for which multichannel coaxial SMA- and SMP blocks are available.

- We have PCB to flex interfaces available upon inquiry.

In the design of our connector solutions, we take the following requirements into account: the connector blocks have low reflections (S11 < -15 dB up to 10 GHz) and low crosstalk (NEXT < -40 dB). Moreover, they should thermalize well and lastly, they should have a small footprint. To reduce the footprint, we are currently developing high-density connector interfaces, which we expect to launch in the second half of 2024.

Coaxial connectors

SMA

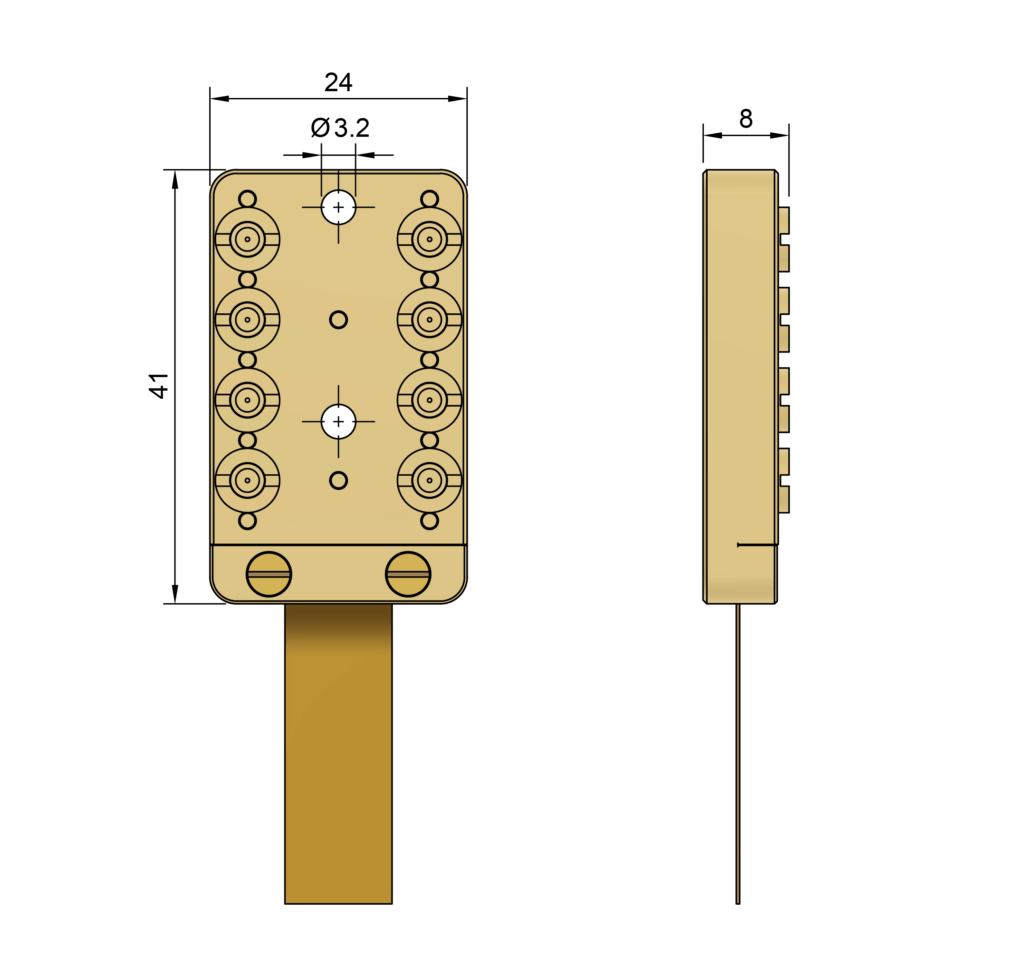

SMA connectors are available in 8 channel blocks. SMA connectors have long been the industry standard because of their sturdy nature and good microwave performance up to 18 GHz. The connector blocks are relatively large to allow tightening the connectors with a torque wrench.

SMP

SMP connectors are available in 8 channel blocks. These connectors are easy to install due to their click-in mechanism. The footprint of these connector blocks is ± 40% smaller than that of the SMA blocks, because of the smaller footprint of the connectors and because screw-in access is not required.

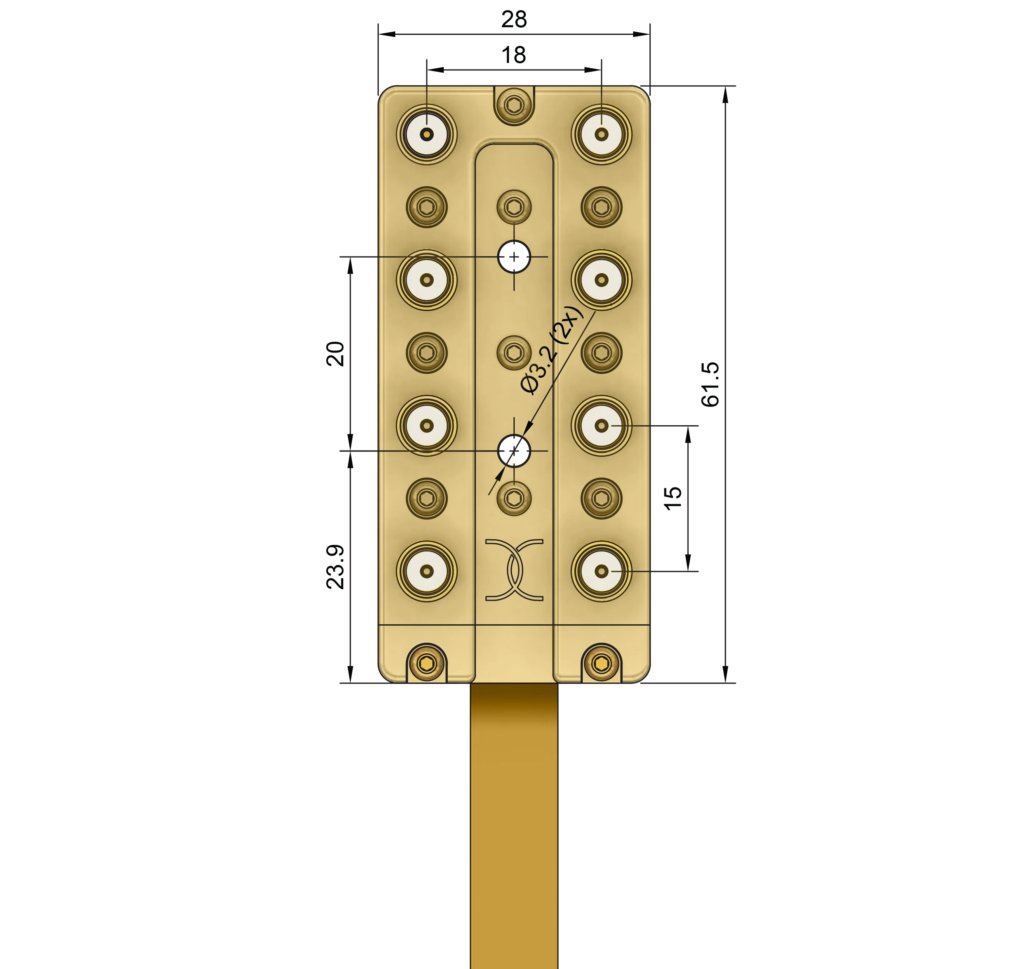

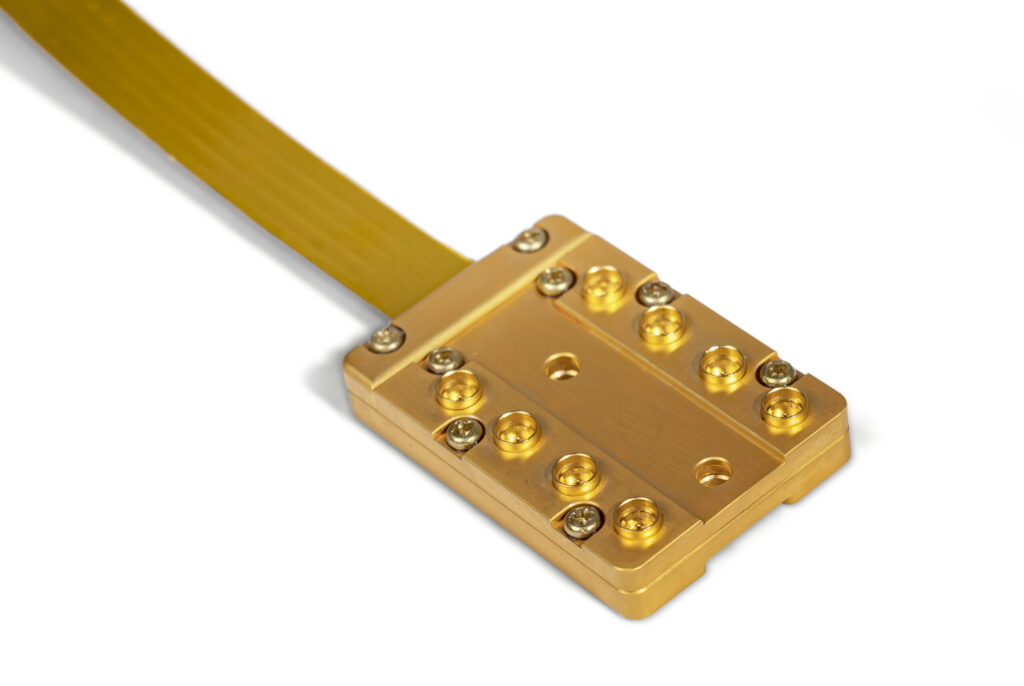

Flex to Flex connectors

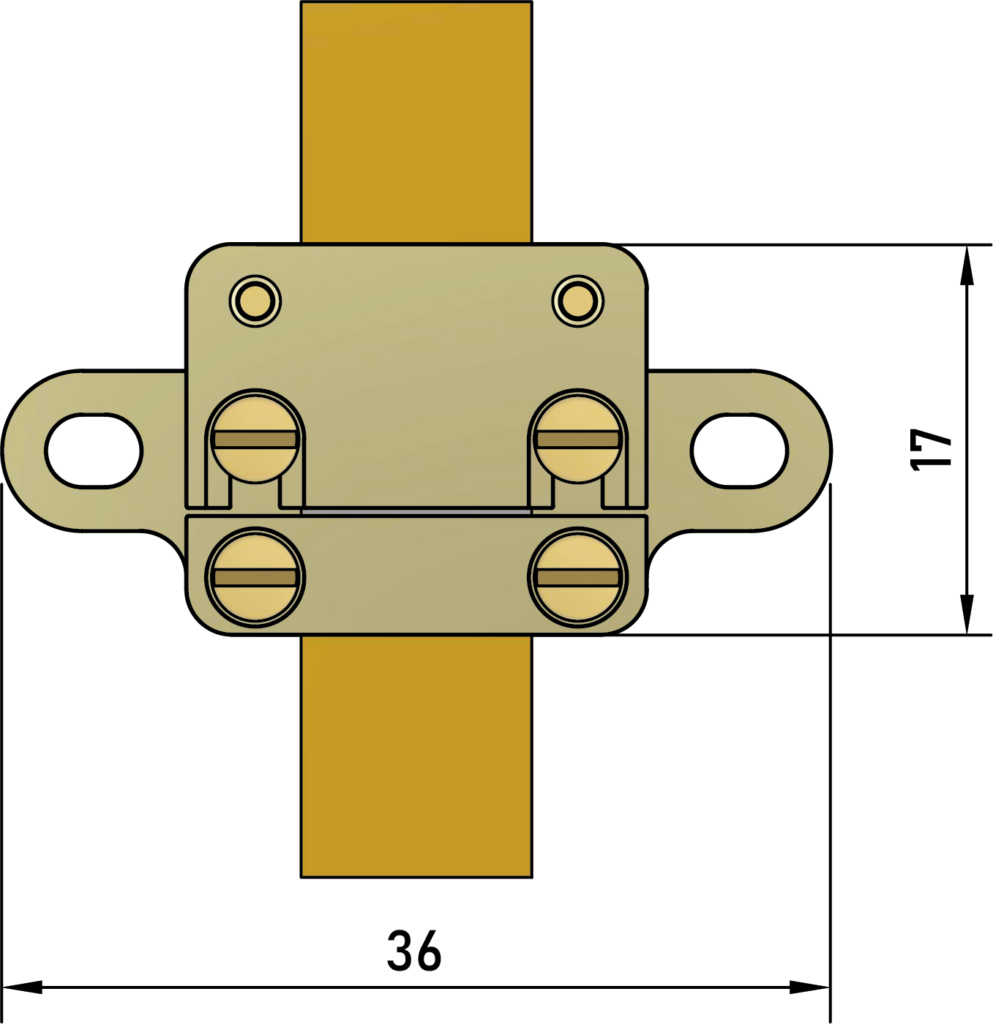

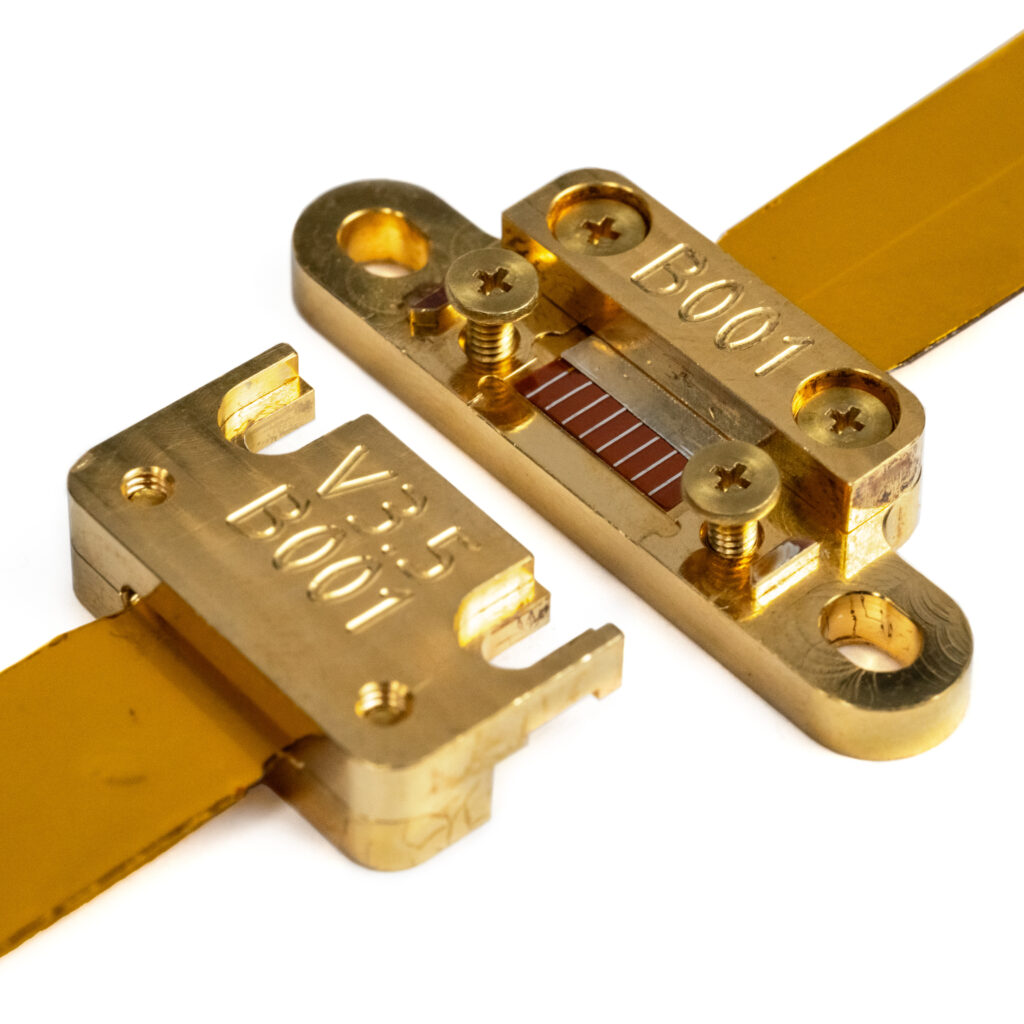

Tabbi/TM

To remove bulky interconnects, while still allowing for modularity in your cryogenic chain, we have developed a flex-to-flex interface to connect two open-ended 8-channel Crio/Flex® 3 cables. This ultra-high density microwave interconnect allows modular configuration of any Cri/oFlex® 3 i/o chain.

Custom High Density Interconnects

In order to connect Cri/oFlex® to your own PCB or packaging please contact our Sales team.

Get in touch

Questions or curious what we can do for you?

Use our contact form for all information requests or contact us directly using the contact information below.

Feel free to get in touch with us via email or phone

Phone

Our location

Netherlands

2627 AN Delft

Schieweg 15A

Contact us directly!

New! Schedule a meeting with our team immediately!

How does Cri/oFlex® handle all

System nodes?

There are mutliple nodes in your system which all require special attentions. We handle all nodes with the care they deserve, specially designed solutions that will handle all kinds of different fridge designs. Wondering how we can help you? Either contact us with your special request or see below for some examples of standard solutions we have engineered.

Room Temperature node

- High density connections

- Reliable vacuum feedthroughs

- High Reliabiliy connections

The top part includes a vacuum feedthrough with 10 slits

Learn more

mK node

- High density connections

- Robust Modularity

- Flex 2 PCB on design

The mK node has the highest requirements for heat load and density, we can solve both!

Learn more

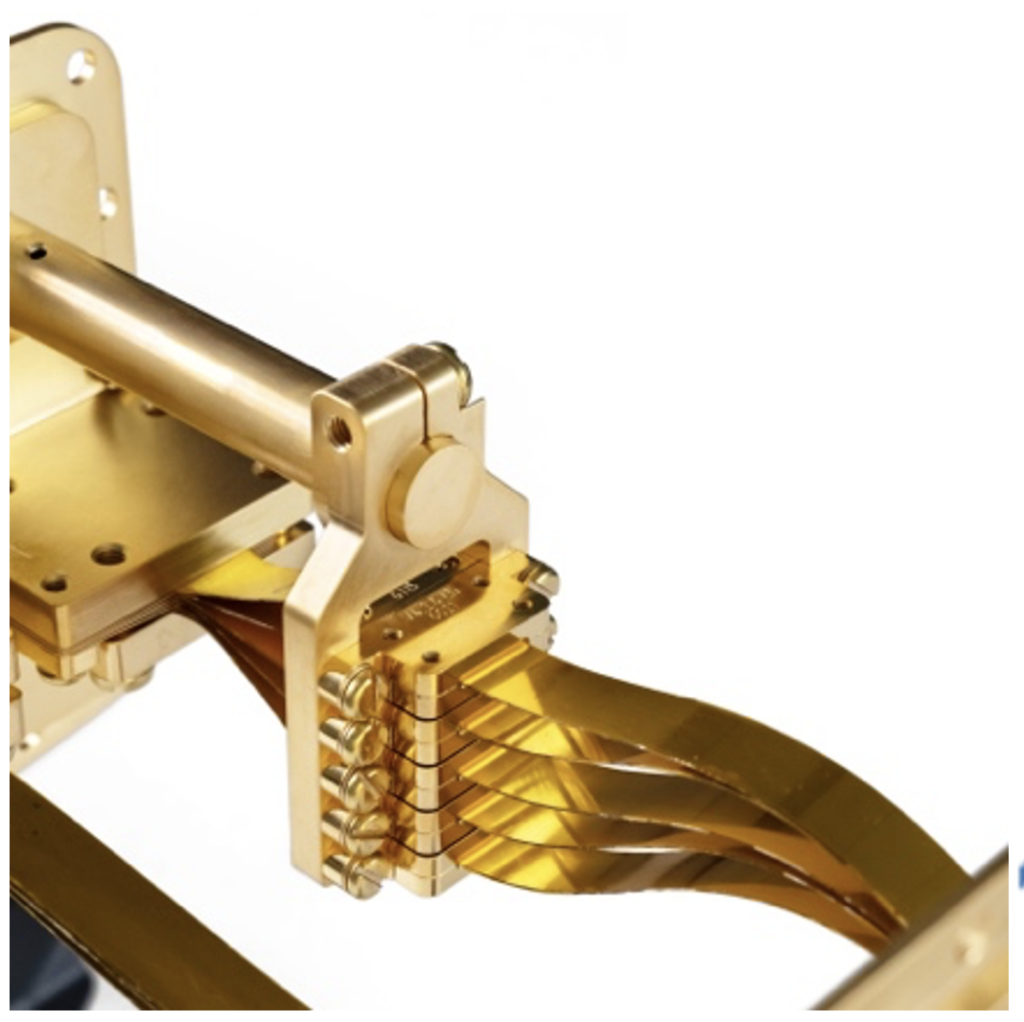

4K node

- High density connections

- Flexible design

- Many 4K amplifier slots

The 4K node can be the transition to NbTi, Delft Circuits provides high denisty flex to flex connections

Learn more