About Delft Circuits

Our Story

The story of Delft Circuits started in 2016, when Delft Circuits’ founders Sal Jua Bosman, Paulianne Brouwer and Daan Kuitenbrouwer started their daily activities. Frustrated by a lack of dedicated quantum hardware to support Sal’s PhD at TU Delft, he then set out the goal to find solutions to the hardware nightmare of Quantum Computing researchers all over the world. In 2017 Delft Circuits b.v. was formally founded, with beta-testing in progress for our Cri/oFlex® products.

Fast-forwarding to now, we rapidly grew to a team of over 40 people and completed in-house cleanroom production and testing facilities. Our proof-of-concept microwave channels have matured to ready-for-sales product lines, and the next steps in production capabilities and microwave components are being developed to expand our product portfolio. After our first sales started in early 2019, we are also proud to say we have customers worldwide, ranging from world-leading national laboratories to global corporations, startups and universities, with Cri/oFlex® Technology making a difference in each of their setups.

Company profile

Delft Circuits is dedicated to supplying the best hardware for the quantum engineer and industry. So far we have realised hundreds of i/o modules, for almost a hundred customers. Whether in a leading national laboratory, a Blue-chip corporation, or an ambitious professor, clients find their way to our solutions. As an independent, dedicated quantum hardware supplier, together with our customers, we make quantum technologies a reality.

Quantum technologies offer revolutionary new capabilities, the industry is booming but is still in its infancy. With quantum computing, a landscape of new possibilities will be added to the thriving eco-system of high-performance computing, machine learning and artificial intelligence. Quantum communication and – internet brings new capabilities in (information) security and distributed (quantum) computing. Finally, quantum sensing will get a whole new dimension to a host of industries and sciences.

In the past two decades, we witnessed an explosion in academic research and results. Now, this development is transitioning into the first steps of the quantum industry, of which we are proudly part. With our team, of 40 now, we are devoted to supplying the quantum engineers in industry, academia and national labs, with the best available tools, technology and services, such that they can focus on their real tasks.

We are an ambitious group of people, ready to realize our vision of paving the way for quantum technologies, by providing innovative and relevant solutions to the hardware challenges of quantum engineers. We are dedicated to supplying the best hardware for the quantum engineer and industry. Together with our customers, we make quantum technologies a reality.

Our Mission

Quantum technologies offer revolutionary new capabilities for mankind, and will most likely affect even more segments of our lives than we can imagine. The industry is booming but is still in its infancy. With Quantum Computing, a landscape of new possibilities will be added to the thriving ecosystem of high-performance computing, machine learning and artificial intelligence. Quantum-communication and -internet bring new capabilities in information/security technologies and distributed computing. Quantum sensing will bring a whole new dimension to a host of industries and sciences. These are just the fields we see today.

In the last two decades, we witnessed an explosive growth in academic research and experimental results related to quantum technologies. Now, this development is transitioning into a quantum industry, of which we are proudly the part. With our team we are devoted to supplying the quantum industry, academia and national labs with the best available tools, technology and services, so they can focus on their real task.

Our Facilities

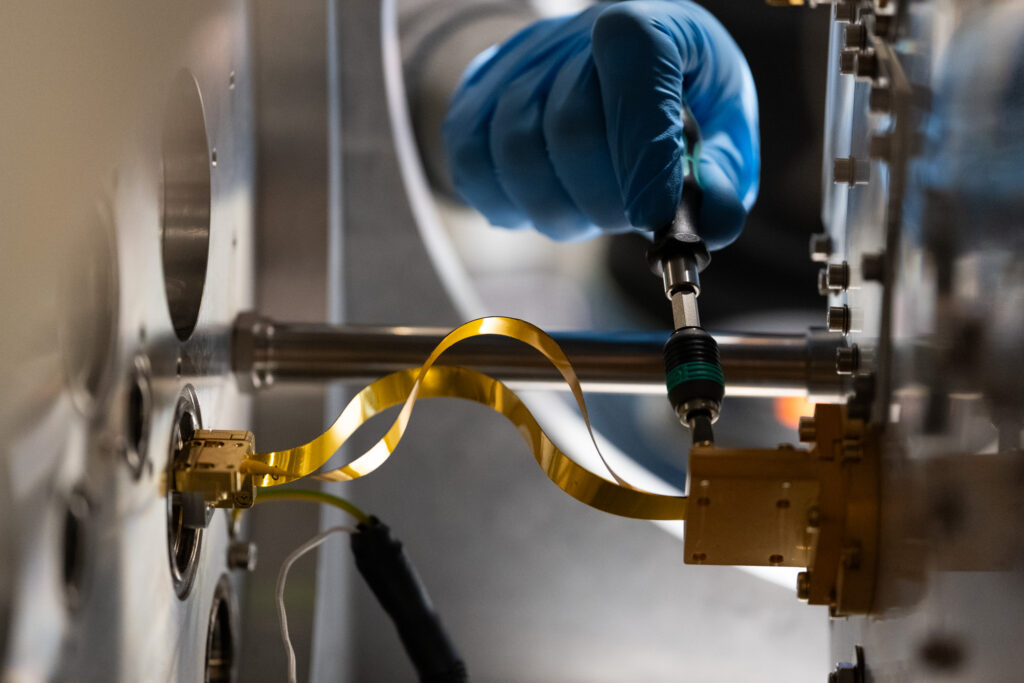

Delft Circuits has an in-house fabrication and pilot-production facility of close to 1000 m2 located at the Kabel District. Our facilities contains a fully-fledged production process, capable of fabricating multi-layer (super)conducting circuits on flexible substrates. Our processes require expertise and equipment including metal deposition, lithography, chemical processing, high-resolution inspection and much more.

To validate our products, we have access to cryogenic and measurement equipment for thermal and electro/ microwave characterisation from room-temperature to 10 milliKelvin.

In 2022, Delft Circuits has expanded to the historic cable factory on the Schiekade in Delft. This is a short walk from our other location at the TU Delft. The site of the former largest cable company in Europe now facilitates more fabrication and office space.

Within the Delft Quantum Campus, we have one of the largest research cleanrooms in Europe. Here we have access to most of the possible fabrication and inspection technologies. We can deposit many superconductors, metals and dielectrics through evaporation, sputtering, ALD, LPCVD, PECVD, etc. We have access to optical and E-beam lithography and inspection like AFM and SEM. With more than a decade of experience in this cleanroom, we are the ideal partner to fabricate your most challenging circuits.

Investors

Delft Circuits is backed by world leading partners. With DeepTech XL, as partners such as ASML, Philips and PME pensions, we have the backing of of world class players in the (semicon) industry. Not only that we are funded by High-Tech Gründer Fund, the leading tech fund from Germany. Complimenting our team with partners as QuVest Capital and Scholt Group and we are fully geared for the quantum industries booming.

Public Projects

EU Horizon 2020

Delft Circuits gratefully acknowledge support from its partners.

Delft Circuits B.V. has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N 946528.

Annealing-based VAriational QUantum processorS (AVaQus)

Delft Circuits gratefully acknowledge support from its partners.

Delft Circuits B.V. has received funding as a partner of AVaQus project by the FET Open initiative from the European Union’s Horizon 2020 research and innovation programme under grant agreement N 899561.

Materials for Quantum Computing (MATQu)

Delft Circuits is happy to be part of the MATQu consortium.

The project has received funding from the ECSEL Joint Undertaking (JU) under grant agreement No 101007322. The JU receives support from the European Union’s Horizon 2020 research and innovation program and Germany, France, Belgium, Austria, Netherlands, Finland, Israel.

Scalable Platform for Quantum Technology (SPROUT)

Delft Circuits gratefully acknowledge support from its partners.

This project has received funding from the Eurostars programme with co-funding by EUREKA member countries and the European Union Horizon 2020 research and innovation programme and the Rijksdienst voor Ondernemend Nederland (RVO).